Tiller Retention

|

Administrator

|

What are YOUR experiences or opinion of taper-fit Vs retaining-pin for tiller retention?

It is interesting to note that Vivier's instructions for tiller retention do not require a pin. He is clear that [Gargle translation] - "The bar [tiller] is given a trapezoidal [tapered] section (in side view) so that it gets stuck [fixes] by pushing it back. To avoid any laborious adjustment, [during construction] simply screw the caliper [cap/bracket] to the rudder while inserting the bar [tiller]" (Source = Wooden-Boat Building-sheets – Fiche 72, Page 2 of 2.) It appears from these pictures that several Morbics are operating with this system, which from an engineering perspective (IMHO) seems pretty sound. What do you think?

|

|

I've just been assembling the rudder stock today and as you say the taper does seem to hold it firmly, although that could be the still tacky varnish! I'm putting a captive split pin in from the side as belt and braces.

|

|

Administrator

|

If it's not too late, and if you are going to fit a pin; have you considered having it vertical, and only through the tiller, ie aft of the stock?

(I'm still intending to rely on the taper.) |

|

I looked at that option but decided it was neater to go through the side of the rudder head. It's quite inconspicuous in amongst the screws holding everything together!

|

|

Some of the boats at my old club, the Scows I think, had a vertical split pin. The main sheet was always getting caught on it. I wouldn't want to risk the tiller coming out at a moment of stress so I'll be having a pin through the side. While we are on the subject I will be having a small pipe cleat on the side of the tiller to hold the rudder up-haul, I don't quite understand or trust the groove carved into the top of the stock in the kit. Can someone enlighten me on how that works? Thanks Graham. Sent from my Xperia by Sony smartphone ---- Jon Dykes [via MyMorbic Sail-&-Oar Dinghy UK Network] wrote ---- I looked at that option but decided it was neater to go through the side of the rudder head. It's quite inconspicuous in amongst the screws holding everything together! If you reply to this email, your message will be added to the discussion below:

https://forum.mymorbic.uk/Tiller-Retention-tp142p145.html

To start a new topic under MyMorbic Sail-&-Oar Dinghy UK Network, email [hidden email]

To unsubscribe from MyMorbic Sail-&-Oar Dinghy UK Network, click here. NAML

Graham Neil

https://port-na-storm.blogspot.com/

|

|

In reply to this post by PaulW

I started out with the taper but after ending up with the tiller in my lap a couple of times I went for the pin option.

|

|

Administrator

|

In reply to this post by Portnastorm

I'll concur with Graham N on not having the pin on the top of the rudder stock.

IF I find a pin is necessary I'll put it in the tiller. And I'd rather have it vertical, to better see the hole when fitting the pin. Worked well on a whaleboat with which I had long-term acquaintance. The safety system on that was a loop of small diameter shock-cord, both to keep the pin in place when in use, and to retain it on a small screw-eye on the aft face of the stock. IMHO a reason to not have a pin-hole anywhere in the stock, is that unlike screw-holes, it becomes one more potentially unprotected hole in plywood. A recipe for water penetration. Maybe we'll hear from Cadfael, Boodicca, & Swefn about their experience of going pin-less. |

|

Administrator

|

This post was updated on .

In reply to this post by Portnastorm

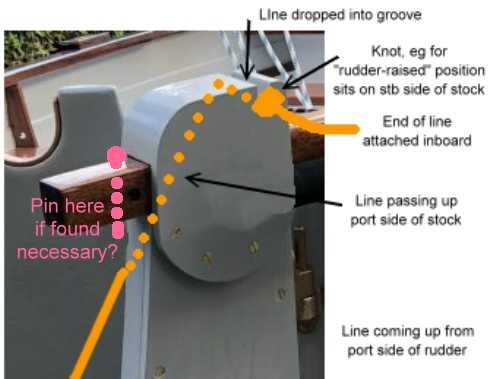

> Graham N (Port-Na-Storm)

AFAIK, the cord & groove works like this. Cord comes up from aft edge of rudder blade and is used for lifting it. Cord is passed across the top of the stock and lies in the transverse groove. Knots are tied at strategic points in the cord to sit on the stock-edge thus preventing the cord from slipping down. Different knot positions would enable a range of rudder depths (if desired). As a safety measure, the tail end of the cord could be fixed to a suitable point on the transom. (Maybe it could even be clove-hitched around the tiller, en-route to the transom.) Vivier says "There is one lifting line. Make 2 knots for lower and tilted position. It is advisable to attach the end of the line to the hull, in order to avoid any loss of rudder" [Morbic 12 building Manual Page 18/21]. |

|

Administrator

|

In reply to this post by Portnastorm

Sketch of assumed application of cord-in-groove rudder-lifting system.

+ PW preferred position for tiller-retaining-pin if required.

|

|

I just used a small cheek block on the side of the stock to tale a line forward to a Camcleat on the tiller. Assuming there is a knot in the end, the tiller can't come out of the stock at any point, and it's easy to keep the blade raised while launching.

Relying on the taper alone is a bit dodgy, as I have already had to tighten mine up with a bit of self-adhesive Mylar sailcloth to make the fit tighter There is, on the drawings, a hole in the end of the tiller, but I've never decided what it's for. Maybe a toggle end pin? |

«

Return to MyMorbic Sail-&-Oar Dinghy UK Network

|

1 view|%1 views

| Free forum by Nabble | Edit this page |