Oars

|

Hi all,

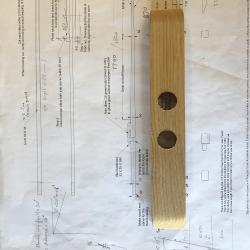

On the final stretch as heading to Rutland Water in a couple of weeks to launch… Can’t wait to escape the garage workshop! I’m a bit stuck with the oars and rowing setup. I have gone with the plan and have made my own oars and am using the thole pin setup rather than rowlock. If you have this setup, might you be able to share any pictures of rowing ‘in action’, and in particular, a close up of the bulls with/without the thole pins in them. Specifically, I assume the rower can move the blades in and out of the water vertically due to play in the bull hole diameter relative to the size of the thole pin? Else I can’t see how you get the blades to move. Is that correct? I’ve shaped and installed the thole boards, and am making the bulls. The pins are 14mm, bull holes specified as 20mm but the plan only has 22mm wide bulls so that doesn’t work for a clumsy amateur like me as I would no doubt rip the bulls when drilling. My plan is to make the holes oval - so 20mm longitudinally and say 17mm transversely. The picture shows round holes at the moment at c16mm before I widen them. Any course correction advised? Thanks, Marc   |

|

Hi Marc,

I'm about at the same stage as you - painting and finishing seems to go on forever and I too am looking forward to leaving behind my narrow garage with less than a foot clearance each side of the boat! I also plan to go the thole pin route. Looking the plans it seems that it is the 35mm face of the bull into which you have to drill a 20mm hole and you carve out that hole generously length wise wrt to the bull to give more oar movement. I have had cause to blow up the drawings on my laptop screen to check dimensions like this. I zoom out on a marked up dimension until it matches the actual dimensions as measured by my plastic rule (to avoid scratching the screen), then I simply drag the part I want to measure until visible on the screen and read off the required dimension. You just have to be careful you don't accidentally zoom whilst dragging the image across the screen. Hope that helps. PS - how many screws have you used to secure your lug-only mast step and where have you put them? All the best Peter

|

|

In reply to this post by Marc Lien

Hi Peter,

Thank you. Your boat looks awesome - congrats! So… looks like I have drilled the hole in the wrong face - the 22mm face rather than 35mm :( No more stock… :( but I have only screwed it so might try and source some sharpish. 2 steps forward, 3 back… This is only the 3rd or 4th massive mess up on my oars - top of the list was mis measuring and cutting the handle off and needing to scarf back on… Here is my mast step… but as per the above, I wouldn’t trust much of what I am doing here. I’m making it up as I go along!

|

|

Hi Marc, I think the odd error here and there are the lot of the amateur boat builder as inevitably we are learning on the job. A couple of weeks ago I fitted the curved trim to the aft deck. My wood (sapele) was smooth on one side but full of planing snags (divots) on the other, which would be invisible as the glued face...so I went and chamfered the ends to fit, offered it up and discovered I had it 'inside out'. Running out of stock, I hand planed another from some much larger stock (a not insignificant task as I have only hand tools), chamfered the ends, only to discover I had chamfered too enthusiastically and it was now too short when bent into its curved position!

Good luck and thanks for the image of where you have screwed the mast step. That was kind of my thoughts too - though I really waned to put a couple of screws at the bulkhead end, but I won't be able to get a drill or screwdriver close enough. Good luck with the oars! Peter PS if you come across any Morbic friendly sized second-hand combi trailers, please let me know as I'm on the hunt for one. |

|

Hi Peter,

I feel your pain! I ended up laminating that bit of trim after snapping it twice! Part of my multi-variate wood on display look :) Back to the saga of the oars, I managed to source some Utile from a timber merchant very close to me. They were brilliant. Spoke to them at 9am, quote by 10am, collected planed and cross-cut product at 3pm. Robbins quoted me 13 weeks!! Highly recommended for any London builders: https://www.pojoycetimber.co.uk/ I treated myself whilst there to a 20mm drill bit, and voila, upgraded bulls. The good thing about these ones is that I am more confident that when I try my oars for the first time, the blades will get wet   |

|

Administrator

|

Nice looking craft Marc* - Are those your home-grown builder's assistants in the background?

Your timber merchant is a useful find (too late for us now) - You've inspired me to start a list of suppliers on the website - In External links. * And yours Peter! Will this be a vintage year for UK Morbics? |

|

Hi Paul,

I would like to recommend Seaware as a great source of fasteners including marine stainless steel and silicon bronze screws of all types and sizes. You can buy screws in their ones and twos if you wish, the website is very easy to use and they post small packets by Royal Mail for £3.95 or thereabouts. They are based in Penryn in Cornwall and I had the opportunity to call in on them when on holiday in Falmouth earlier this year. It's a super organised well run Alladin's cave. They are also very friendly and helpful. Link https://www.seaware.co.uk/ Regards Peter |

|

Administrator

|

Hi Peter – Seaware – Thanks – I had been trying to remember the name. Robin had sourced some of our bits three.

Now on website, along with a few others (and room for more!) :-)> PW |

|

Hi again Paul - thanks for adding this to the website. Seaware also sell bronze screws and fixings - might be worth adding this to the description? Atb. Peter

|

|

In reply to this post by Marc Lien

My turn now - just finished my pair of ‘bulls’ only to discover I had chamfered the wrong faces at the ends! I wouldn’t mind only I hand cut the oak stock (with a rip saw) and then hand planed it 😩

Peter

|

|

Ouch. I feel your pain Peter. The good news is that the thole pin - thole board setup works really well in practice. On my last little boat, I struggled to use normal oarlocks as a total newbie, but with this Morbic setup, I managed to row a good distance even in a blow from both stations.

I’m still working through the best way to secure the thole pins so they neither pop out, nor drop into the boat, nor require a tonne of setup. The only minor drama from my Rutland launch week was losing a thole pin  as the whipping worked its way loose and the pin plopped over board! I console myself by thinking about the bronze bling I’ve added to the bottom of the lake as the whipping worked its way loose and the pin plopped over board! I console myself by thinking about the bronze bling I’ve added to the bottom of the lake  Best of luck with the finishing touches. Marc |

«

Return to MyMorbic Sail-&-Oar Dinghy UK Network

|

1 view|%1 views

| Free forum by Nabble | Edit this page |